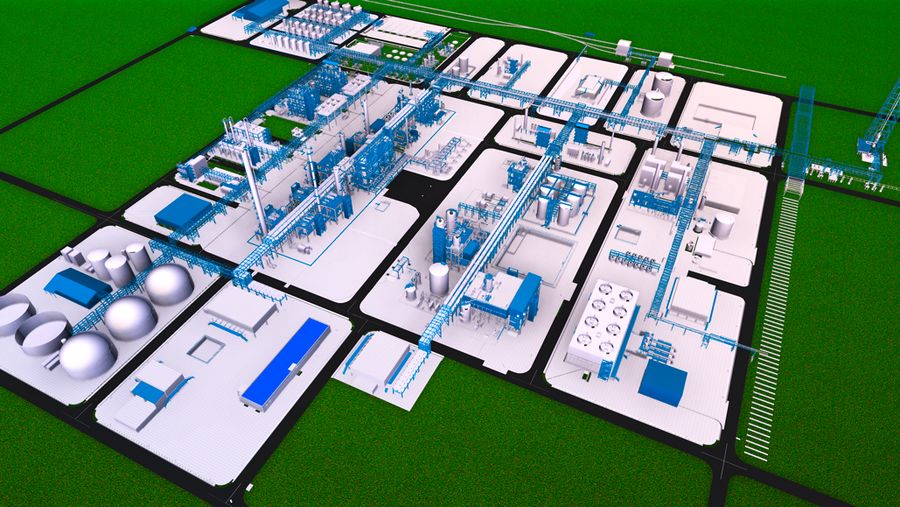

MOL Hungarian Oil and Gas Public Ltd., a leading international oil and gas company, has awarded a contract to the Electrolysis & Polymers Technologies business unit to build a polyol complex. The MOL group is investing a total of around 1.2 billion euros in the project. The contract for the engineering, procurement and construction of the chemical complex was signed on 12 September 2018. The complex with an annual production capacity of 200,000 tons of polyether polyol will be built in the northern Hungarian town of Tiszaújváros, 160 kilometers from the capital Budapest, close to an existing MOL refinery.Polyether polyols are needed to produce polyurethane, an important material for products in the automotive, packaging and furniture industries.

New standards of efficiency, environmental friendliness and automation

Marcel Fasswald, COO of thyssenkrupp Industrial Solutions: “The new polyol complex is an important flagship project both for us and for our customer MOL and Hungary. Together we will set standards in terms of efficiency, environmental friendliness and automation by combining proven technologies with innovative solutions. We look forward to our further cooperation and are proud to contribute our decades of experience in chemical plant engineering and the handling of such major projects. At the same time, we are strengthening the plant engineering business of thyssenkrupp.”

Reaching the final investment decision on the polyol project and the signing of the EPC contracts with our renowned strategic partner, thyssenkrupp, is another major milestone of our transformational strategy, MOL 2030.

Zsolt Hernádi,

Chairman and CEO of the MOL Group

Project execution: Six sites on two continents form a close network

Peter Sieben, head of the business unit: “We will be cooperating closely on this ELP project at six sites across two continents. The project management team, who will be the direct point of contact for the customer, will be in Bad Soden (Germany). Engineering will be performed by colleagues in Dortmund (Germany), India and Thailand, while construction will take place in Hungary. Procurement will be carried out by colleagues in China and Thailand among others.”

Impressive figures underline size of project

The following figures illustrate the huge dimensions of this project: Around one million engineering hours will be needed, roughly 350 thyssenkrupp employees will be involved in the project, up to 4,000 people will work on the construction site at the same time. The site for the complex measures 900 x 600 meters, construction will involve 12,000 tons of steel and 100,000 cubic meters of cement, and up to 500,000 cubic meters of soil will have to be moved.

The MOL contract is the latest high point of thyssenkrupp’s longstanding activities in Hungary. It all started in 1878 with the first Krupp branch office in Budapest. In 1971 Polysius built a cement plant – at the time the biggest and most advanced in Eastern Europe. In 2003 and 2004 MOL placed orders with Uhde to build plants for the production of low-sulfur diesel and the hydrogenating desulfurization of diesel fuel. In 2018 the Components Technology business area opened a plant for steering systems and engine components with around 500 employees.